Overview of IO-Link

What is IO-Link?

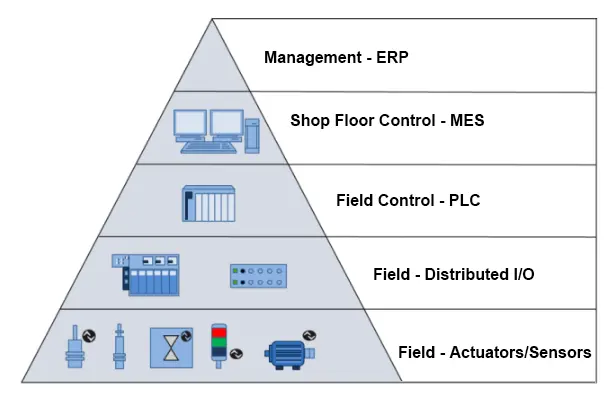

IO-Link is a digital communication protocol used in industrial automation, initially proposed by Siemens and now an international standard. It is designed to enable connection and communication between industrial devices and control systems. It allows sensors, actuators, and other industrial devices to communicate bidirectionally with controllers (such as PLCs), enabling the real-time transmission of data and control signals.

IO-Link is a serial communication protocol (similar to I2C bus), and serves as the communication standard for industrial controllers and industrial actuators or sensors. It is the “last few feet” technology standard for connecting communication networks to the field level.

Why is IO-Link Needed?

The need for IO-Link technology arises from the following technical advantages:

- Real-time Data Transmission and Control: In industrial automation, real-time data transmission is critical for accurate control and monitoring of equipment. IO-Link provides a high-speed, reliable digital communication channel, allowing sensors and actuators to quickly transmit data to the control system for real-time control and monitoring.

- Bidirectional Communication: IO-Link enables not only the reception of instructions and configuration information from the control system but also the transmission of parameter and status information back to the control system. This intelligent communication allows devices to adapt to different production requirements and working conditions, enhancing flexibility on production lines.

- Simplified Installation and Maintenance: IO-Link devices can be parameterized and configured through digital communication, reducing human intervention and errors, simplifying the installation and maintenance process. Additionally, IO-Link can transmit diagnostic information, helping engineers quickly identify and resolve issues, reducing downtime.

- Fault Diagnosis and Predictive Maintenance: Diagnostic information transmitted by IO-Link helps businesses perform fault diagnosis, promptly detect and address issues, reducing production interruptions and losses. Moreover, by monitoring the condition and performance data of equipment, predictive maintenance can be implemented, preventing equipment failures in advance and improving production efficiency.

- Standardization and Interoperability: IO-Link is an internationally standardized communication protocol, and devices from different manufacturers follow the same communication standards, enabling interoperability between different devices. This allows businesses to flexibly choose and integrate devices from different manufacturers without worrying about compatibility issues.

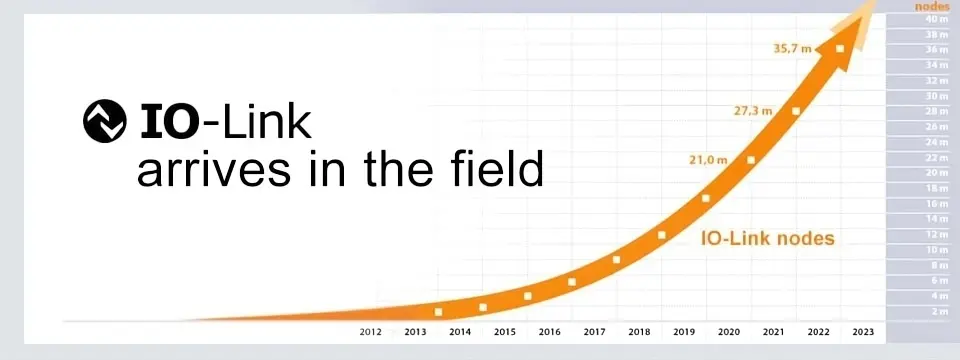

Development of IO-Link

The number of IO-Link nodes has grown exponentially in recent years, reaching 40 million nodes by 2023.

Traditional Sensor Acquisition Methods

Sensor Modes

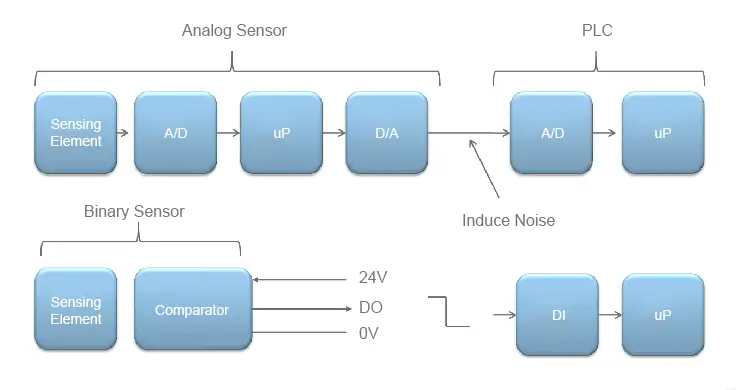

There are two traditional types of data-acquisition sensors:

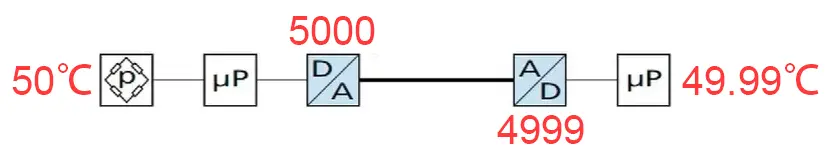

- Analog Sensors: These sensors convert analog values to digital values using an A/D converter. The digital values are then read by a microprocessor (uP) and converted back to analog signals using a D/A converter before being transmitted to the PLC. The PLC uses an A/D converter to convert the analog signal back into a digital value, which is then read by the microprocessor to acquire sensor information.

- Binary Digital Sensors: These sensors transmit binary digital level signals (DO, DI) between the sensor and PLC.

Single-Port Binary Digital Sensor Driver

What is a sensor driver, and what functions does it serve?

A sensor driver is a software or hardware component used to control and operate sensor devices, allowing them to function properly and communicate with other systems. The driver converts the physical signals generated by the sensor into digital signals, which are then transmitted to higher-level applications or systems for processing, analysis, and decision-making.

Functions of Binary Digital Sensor Drivers:

- Signal Adapting: Binary digital sensors may generate specific digital signals representing different states or events (e.g., switch states, button presses). The sensor driver adapts these signals into electrical signals, such as voltage, that other systems can read and understand.

- Signal Amplification or Attenuation: Sometimes, the signals generated by sensors may need amplification or attenuation to meet the requirements of subsequent circuits. Sensor drivers can amplify or attenuate the signals to ensure accurate transmission.

- Electrical Isolation: To isolate sensors from noise or interference from other circuits, sensor drivers can provide electrical isolation, ensuring signal accuracy and stability.

- Signal Filtering: Sensors may be affected by environmental noise. Sensor drivers can offer filtering capabilities to help eliminate noise, ensuring more reliable signals.

- Logical Conversion: The output signals of some digital sensors may need logical conversion, such as signal inversion or combining multiple signals. Sensor drivers can perform these logical operations.

- Power Supply for Sensors: Some digital sensors may require external power to operate. Sensor drivers can provide the appropriate supply voltage for these sensors.

- Interface Compatibility: Sensor drivers can provide various interface options for connecting sensors to different types of systems or devices, such as analog signals, digital signals, or serial communication.

Disadvantages of Single-Port Binary Digital Sensor Drivers:

- Data transmission is one-way (read-only).

- Data has only two states: 0/1.

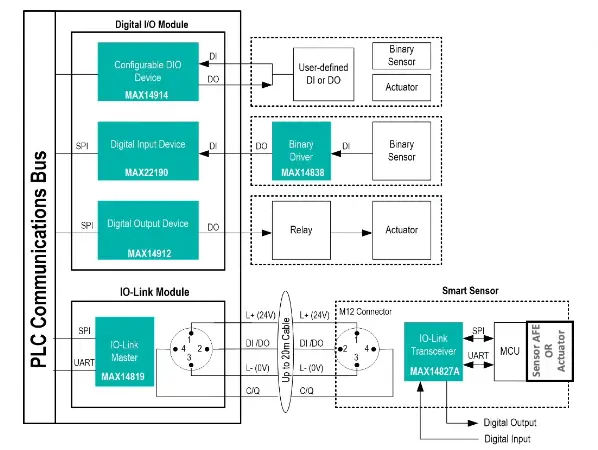

IO-Link Device System

IO-Link Sensors with No Measurement Deviation

Traditional analog signal transmission (e.g., temperature, pressure) requires conversion between analog and digital signals, which can introduce data discrepancies, affecting accuracy.

When using IO-Link connections, measurement values are directly transmitted in a digital format from the sensor to the controller, ensuring that the transmitted data is always consistent with the actual measurement values.

IO-Link connections also avoid the interference issues that affect traditional analog signal transmission, such as electromagnetic noise.

IO-Link Network Components

IO-Link Master Module + GSD File

| Renhotec IO-Link Master | ||||

|---|---|---|---|---|

| Image |  |

|

|

|

| P/N | RHT-920105-08-034 | RHT-920105-08-043S | RHT-920105-08-033S | RHT-920105-08-033 |

IO-Link Ports: These are physical terminals/connectors or logical channels used for connecting IO-Link devices. Each channel can support multiple IO-Link devices. Compact IO-Link master modules with 8 multifunctional ports provide the most intelligent way to connect IO-Link devices, replacing complex wiring and expensive terminal boxes.

IO-Link Hubs

| Renhotec IO-Link Hubs | |||

|---|---|---|---|

| Image |  |

|

|

| P/N | RHT-920105-08-031 | RHT-920105-08-044S | RHT-920105-08-031S |

With IO-Link hubs, multiple digital sensors and actuators can easily be connected to a single IO-Link master port using standard sensor cables. IO-Link hubs help minimize machine and system downtime. Diagnostic information for each channel is automatically transmitted to the control system. No configuration is required. If an error occurs, only the affected channel on the hub is shut down.

IO-Link Terminal Devices + IODD File

Power Supply

Indicator Light

IO Link Analog Converter

IO-Link can be used with various terminal devices:

- Sensors: Temperature, pressure, photoelectric, flow, etc. IO-Link sensors provide digital sensor data and support remote configuration and monitoring.

- Actuators: Solenoid valves, motor drivers, servo drives, etc. With IO-Link, these actuators can be remotely controlled, monitored, and diagnosed.

- Analog-to-Digital (ADC) / Digital-to-Analog (DAC) Converters: By connecting analog-to-digital converters, analog signals can be output from the IO-Link network.

- Identification Devices: Such as RFID readers, barcode scanners, etc., for object identification and tracking.

- …

IO-Link Analog-to-Digital Converter

The IO-Link Analog-to-Digital Converter enables easy connection of analog sensors and actuators to the IO-Link master, allowing traditional analog devices to connect to the IO-Link master station.

While many sensors and actuators are designed for digital IO-Link applications, traditional analog sensors and actuators still need to be integrated into installation concepts. The IO-Link Analog-to-Digital Converter is the fastest, simplest, and most cost-effective way to integrate the advantages of IO-Link into traditional analog sensors. It converts analog signals into digital signals that comply with the IO-Link protocol standard, enabling the connection of various types of analog devices to the IO-Link master.

IO-Link Bus Interconnection (Unified Wiring Standard)

| IO-Link Data Cable | |||

|---|---|---|---|

| Image |  |

|

|

| P/N | RHT-120105-56-007 | RHT-120105-56-120 | RHT-120105-30-005 |

| Electrical parameters | 4A 250V | 4A 125V | 4A 250V |

| No. of Pos | 5 | 5 | 5 |

| Coded | A CODE | A CODE | A CODE |

| IO-Link Power Cable/Accessory | ||||

|---|---|---|---|---|

| Image |  |

|

|

|

| P/N | RHT-121005-56-001 | RHT-780005-56-001 | RHT-120105-10-008 | RHT-120105-10-004 |

| Electrical parameters | 4A 250V | 12A 300V | 4A 6V | 4A 60V |

| No. of Pos | 5 | 5 | 4 | 4 |

| Coded | L CODE | / | A CODE | A CODE |

| IO-Link Signal Cable | ||||

|---|---|---|---|---|

| Image |  |

|

|

|

| P/N | RHT-120404-56-007 | RHT-120404-57-001 | RHT-120404-57-015 | RHT-940004-77-001M |

| Electrical parameters | 4A 250V | 4A 250V | 4A 250V | 4A 250V |

| No. of Pos | 4 | 4 | 4 | 4 |

| Coded | D CODE | D CODE+RJ45 | D CODE+RJ45 | RJ45 |

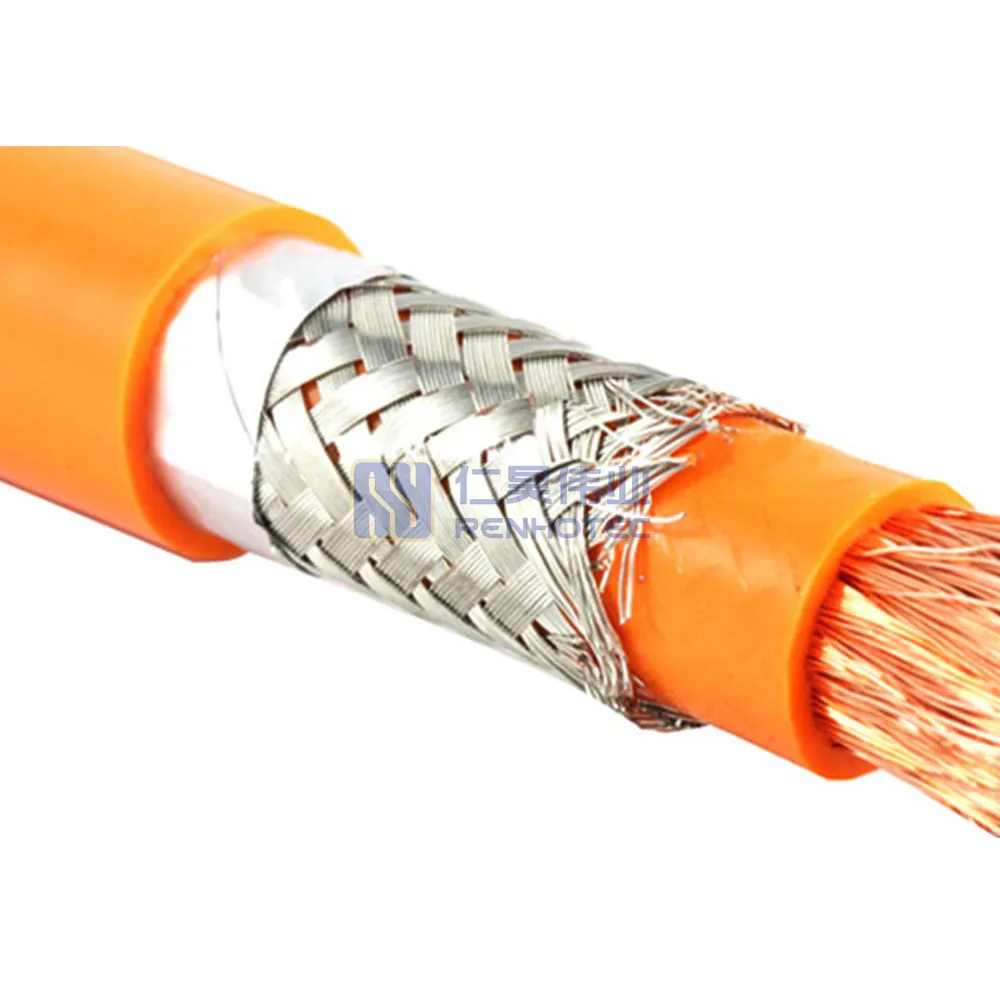

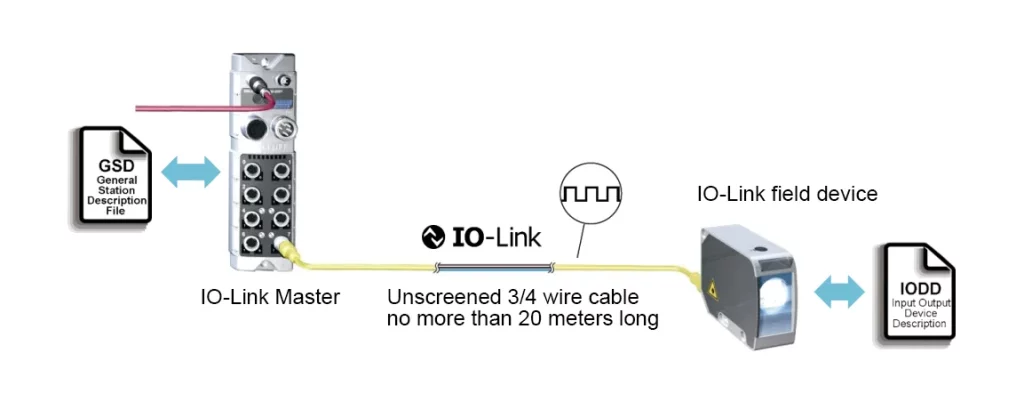

- Signal Line: Connects the master station to the hub or IO-Link terminal devices. The physical layer signaling of IO-Link occurs over this signal line (standard three-wire cable).

- Data Line: Connects the master station to the higher-level control device, such as Ethernet devices.

- Power Line: Supplies high current to the master station.

IO-Link Unified Wiring Standard:

- IO-Link Master only requires a standard three-wire cable to connect all IO-Link devices.

- Digital and analog signals can both be transmitted using the same three-wire cable to communicate with the upper-level controller.

- Forecast: In the future, all analog signals, RS232, and RS485 will be replaced by IO-Link.

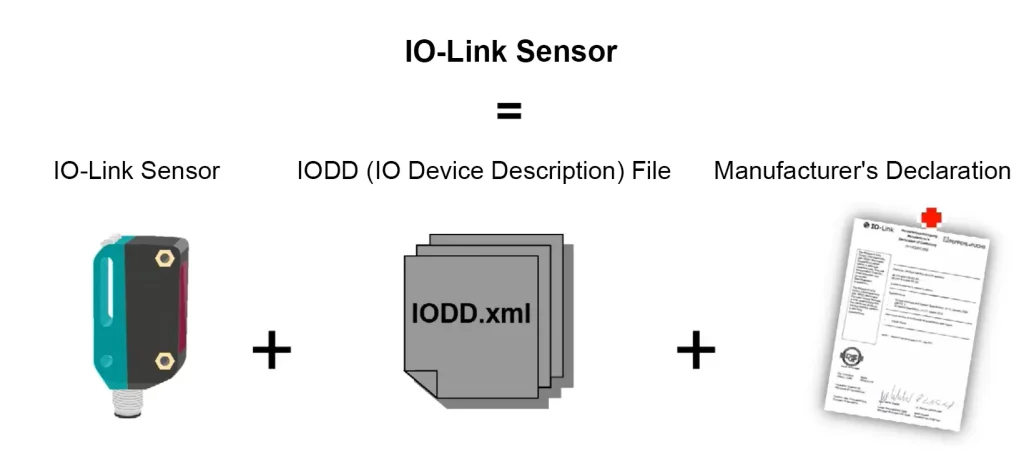

IO-Link Sensor Specification

IO-Link Sensor = IO-Link Sensor (with IO-Link interface and logo) + IODD device description file + Manufacturer Declaration

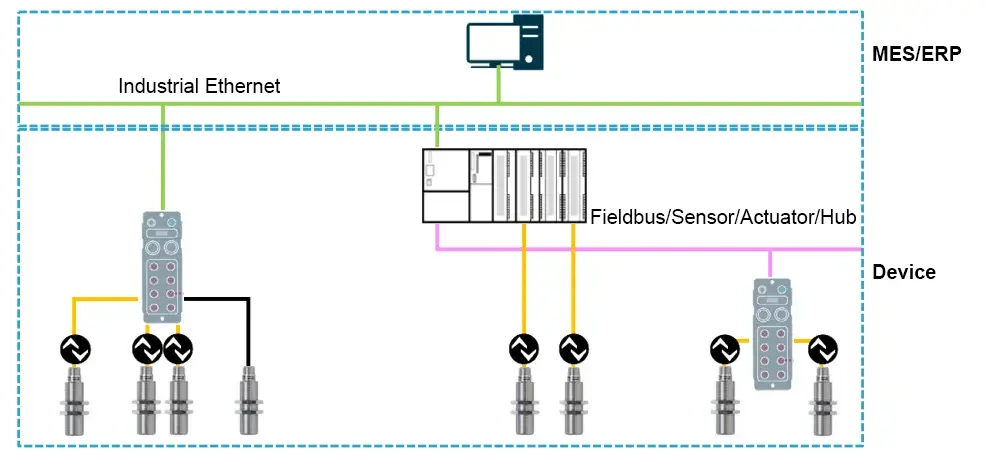

IO-Link in Industrial Networking Applications

IO-Link Communication

Communication Interface and Data Types

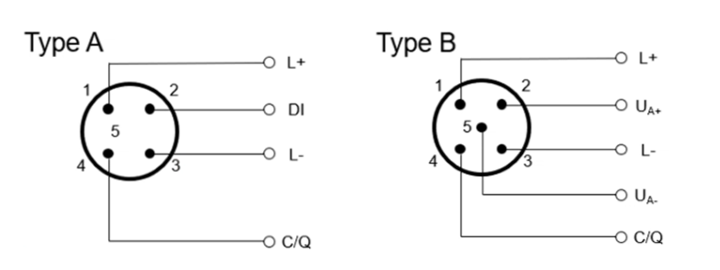

Differences between Type A and Type B:

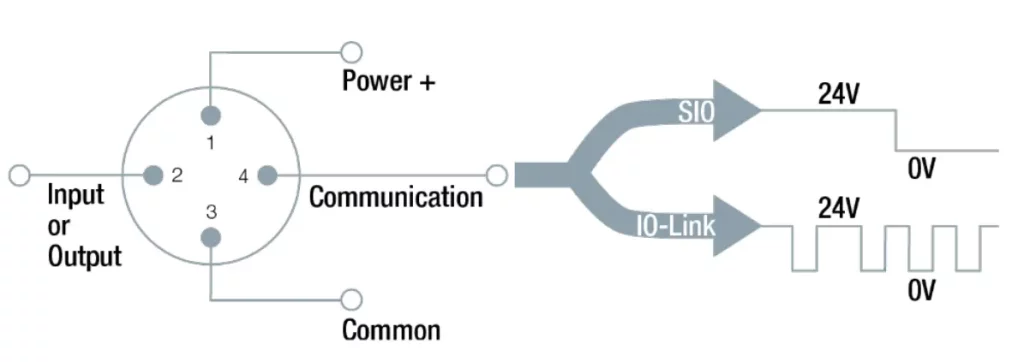

Communication between the IO-Link master and slave devices is done via physical wiring, including power, data, and signal lines. Traditional IO sensors/actuator signals are periodically collected by the master device in the standard IO (SIO) mode. As shown above, Pins 1-4 are the physical wiring pins between IO-Link devices. The functions of each pin are as follows:

| Pin | Signal | Description |

| Pin1 | L+ | 24V High Level |

| Pin2 | ||

| Pin3 | L- | Ground Wire |

| Pin4 | C/Q | Data and Signal Switch |

Data is transmitted through Pin 4 using a 24V pulse-modulated serial UART protocol. The data types transmitted include process data, parameters, diagnostics, and other service-related data.

This is similar to the data transmission in CANopen, where process data and service data correspond to PDOs (Process Data Objects) and SDOs (Service Data Objects) in CANopen.

The communication speed of IO-Link devices depends on the device being connected. There are three modes:

- 4.8KBaud (COM1)

- 38.4KBaud (COM2)

- 230.4KBaud (COM3)

IO-Link data types are as follows:

| IO-Link Data | Data Exchange | Data Size | Transmission Time |

|---|---|---|---|

| Standard I/O | SIO Mode Periodic,Binary |

1 bit | < 0.1ms (COM2: 38.4 Kbit/s) |

| Process Data | Periodic,Serial | 1~32 bytes | 2.3~32ms (COM2: 38.4 Kbit/s) |

| Service Data (Parameters&Diagnostics) |

Non-Periodic,Serial | 1~32 bytes | 2.3~32ms (COM2: 38.4 Kbit/s) |

- Process Data: The most common data type, used to transmit actual physical measurements from sensors, such as temperature, pressure, flow, etc. It is typically used in monitoring and control applications.

- Service Data:

- Parameter Configuration Data Pack: Used to set and configure IO-Link device parameters, such as sampling frequency, operating mode, thresholds, etc. The master device can send configuration data to modify the device’s behavior and functionality.

- Diagnostic Data Pack: Used to transmit device diagnostics information, including error codes, warning messages, fault statuses, etc. These data packets help in fault diagnosis and maintenance.

- Identification Data Pack: Used to transmit device unique identifiers, production information, etc., to prevent counterfeiting. This helps in identifying and managing different devices.

- Status Data Pack: Transmits device operating status, operating time (technical support time), alarm information, status changes, etc.

- Device Function Data Pack: Transmits information on the device’s features and functionalities, such as supported operating modes, data formats, etc.

- Standard IO: Transmits event-triggered signals, such as events triggered when a device reaches a certain state or condition.

The diagram above shows the data transmission process between the IO-Link master and slave devices. As seen in the diagram, IO-Link provides advantages over traditional sensors in terms of data transmission. With IO-Link, sensors not only upload collected data to higher-level systems, but the system can also send data back to the sensors or actuators. The data transmission process is very fast, typically taking 2-3 ms.

IODD Files

The Importance of IODD Files

- Every IO-Link device must provide an IODD file.

- The IODD consists of a collection of files created by the device vendor and standard definition files.

- The IODD contains information on device identification, communication characteristics, parameters, process data, and diagnostic data.

- IO-Link tools combine information from both file groups to provide a complete device description.

- IO-Link tools are used for parameterization and diagnostics of IO-Link devices based on the IODD.

Interpretation of IODD Specification (V1.1)

- An IODD is a formal description of an IO-Link device consisting of files (XML and PNG).

- The file collection includes the main IODD file, optional language files, and optional image files.

- The IODD may contain text in different languages, stored in separate files.

- The image files must be in PNG format, and referenced images can be stored in separate files.

Once the IODD file is completed, it must pass the official IO-Link checker before it can be released.

The main IODD file includes the following information:

- Document Info

- Profile Header

- Profile Body

- Communication Network Profile

- External Text Collection

- Stamp

IODD Generation and Tools

TEC: IODD Designer

- Compatible with versions V1.0/V1.1

- No need for XML-related knowledge

- Integrated IODD Checker functionality

- IODD file import functionality

IO-Link Device Development and Testing

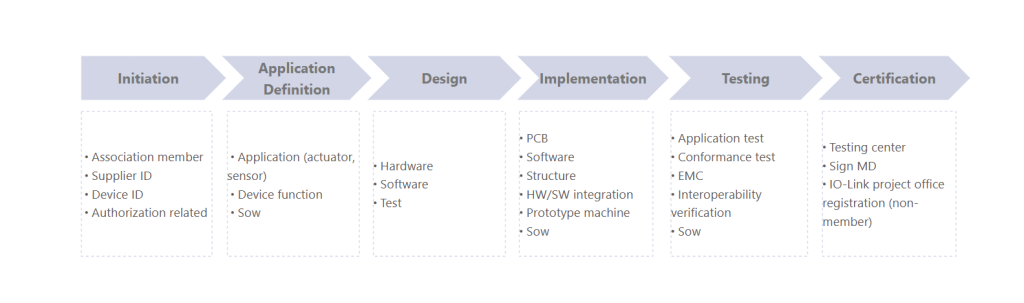

IO-Link Device Development

Application Definition:

- Actuator or sensor functionality

- Definition of cyclic data (process data)

- IO-Link device functions (parameters, events, system commands, data storage)

MCU Selection:

- COM2: Recommended 8-bit processor

- COM3: Recommended 16-bit, such as Cortex-MO or higher

- Typical performance parameters:

- 6-15 MHz

- Flash, +/- 16 kByte

- RAM, +/- 0.5 kByte

- Current consumption, <10 mA

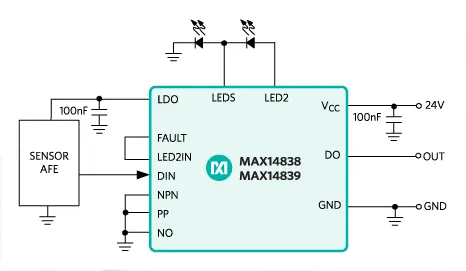

PHY Chip Selection:

- Two typical PHY chips

- Basic functions

- Wake-up request detection (WURQ Detection)

- RX, TX C/Q

- TX enable

- All communication speeds, Hi-side, Low-side, Push-Pull output

- Integrated frame processing

- SPI, I2C

- UART

- Basic functions

- Additional features:

- LDO, DC/DC converter

- Temperature sensor

- Reverse polarity protection

- RC oscillator / PLL as crystal replacement

- Switching modes NPN, PNP, Push-Pull…

- Hot swap, line protection…

What is a PHY Chip?

A PHY chip, short for Physical Layer chip, refers to an integrated circuit used for processing communication at the physical layer in computer networks. The physical layer handles the actual transmission of data and the conversion of electrical signals, transforming logical data into a format suitable for transmission over the network.

PHY chips are commonly used in various network protocols, including:

- Ethernet PHY chips: Used for Ethernet communication, converting data frames into appropriate electrical signals for transmission.

- USB PHY chips: Used for USB (Universal Serial Bus) interfaces, converting USB device data for transmission.

- PCIe PHY chips: Used for PCI Express interfaces, handling high-speed data transfer between PCIe devices.

- Wireless communication PHY chips: Used in wireless communications such as WiFi, Bluetooth, and mobile networks. These chips convert data into wireless signals and vice versa.

- Fiber optic communication PHY chips: Used in fiber optic communications, converting data into optical signals for transmission through fiber optics.

Conformance Testing

Why perform conformance testing?

Conformance testing is aimed at verifying whether a device, system, or application is correctly implemented and operates according to the IO-Link standard.

- Conformance testing must be performed before releasing an MD (Machine Device).

- The IO-Link Quality Work Group is responsible for drafting and maintaining these standards.

- The document provides detailed specifications for testing master and device technology.

- It includes device specification details for testing equipment.

- The documents can be obtained from the IO-Link website.

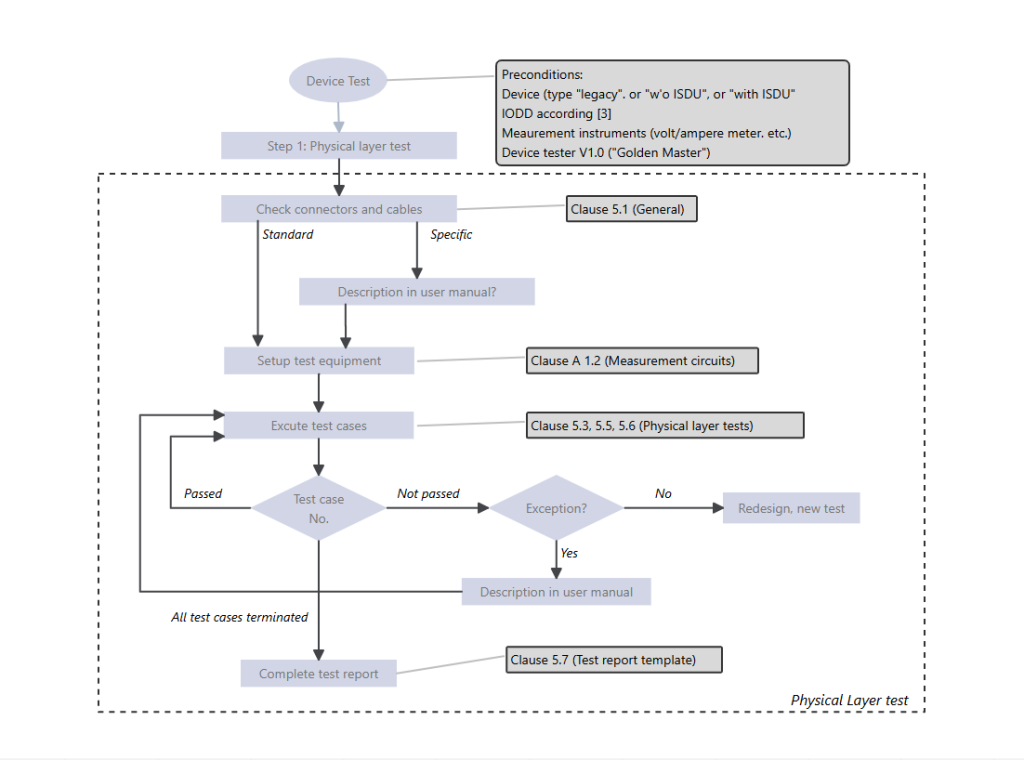

Test Items:

- Physical Layer Test: Physical layer tests require electronic equipment and are usually performed manually.

- Protocol Test: Protocol tests should be conducted using an IO-Link Technology Committee-approved protocol testing system.

- EMC Test: EMC tests are specified in the IO-Link interface standards and require specialized electromagnetic compatibility testing equipment.

The following diagram shows the entire conformance testing process:

IO-Link Configuration Under Different Bus Systems

IO-Link and Bus System Relationships

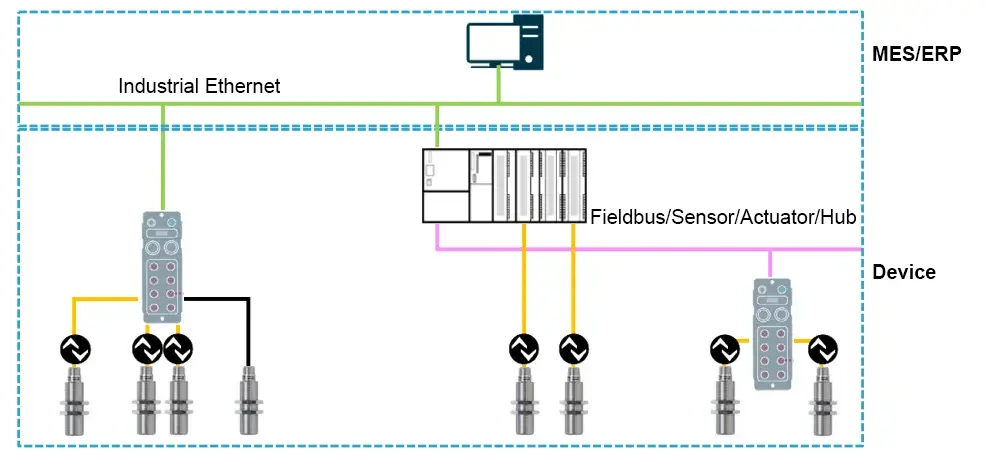

As shown in the diagram above, IO-Link does not interfere with the bus system. On the contrary, IO-Link fills the “last mile” gap between the controller and the sensors or actuators, and is not in competition with the bus but rather integrates and standardizes the entire system.

- IO-Link is independent of existing bus technologies and can be integrated into current bus systems.

- It uses standard M12 and M8 connectors with 3-pin and 5-pin cables.

- Unified interface capable of transmitting DI, DO, and analog signals.

Summary of IO-Link Configuration:

- IO-Link is compatible with mainstream bus protocols.

- IO-Link system components are simple and easy to set up with low cable requirements.

- Configuration under different bus systems is similar and communication is established based on the required input/output process data size of the slave devices.

- IO-Link communication diagnostics are easy to implement.

- IO-Link communication allows easy access to various data from devices, facilitating maintenance and monitoring.