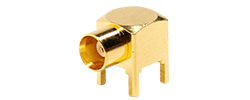

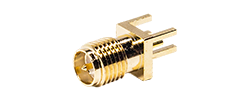

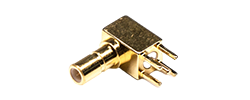

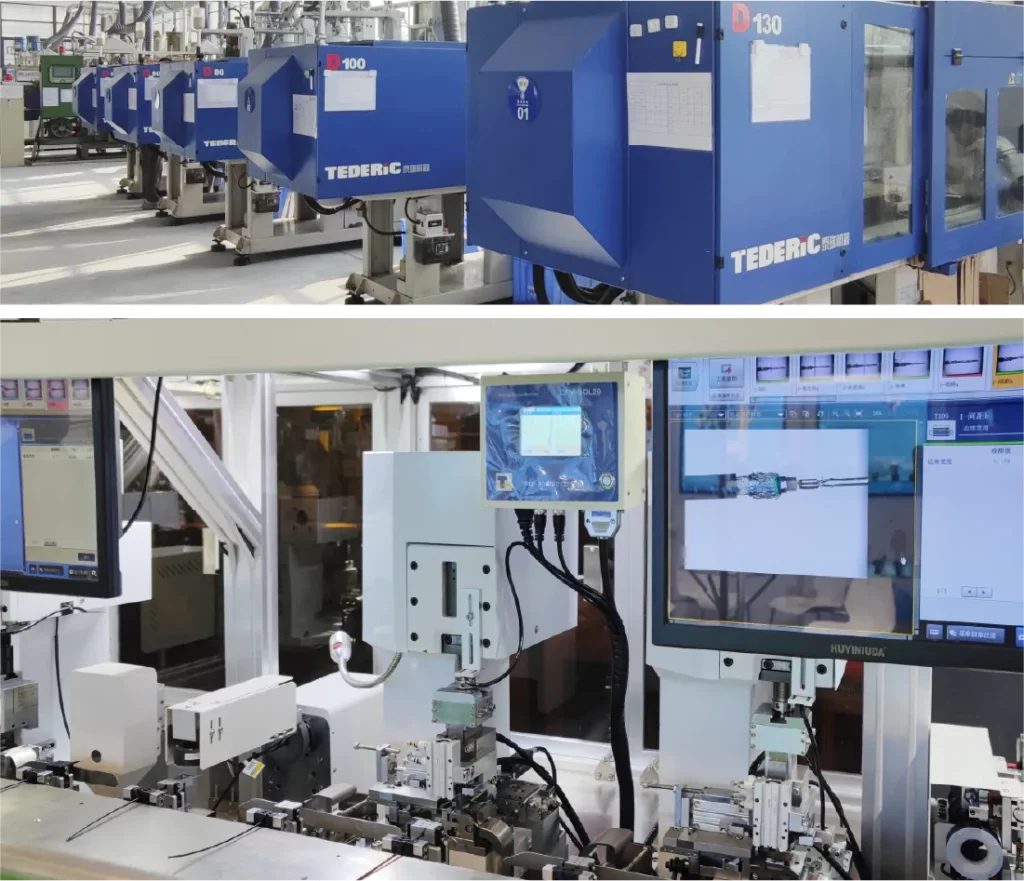

WELL-ESTABLISHED

PRODUCTION CENTER

MOULD

DESICN PROCESS

We design precision Zinc Alloy, Aluminum Alloy and plastic

mould for connector production. With professional equipment

and engineer to support the precision connector dimension

requirement.